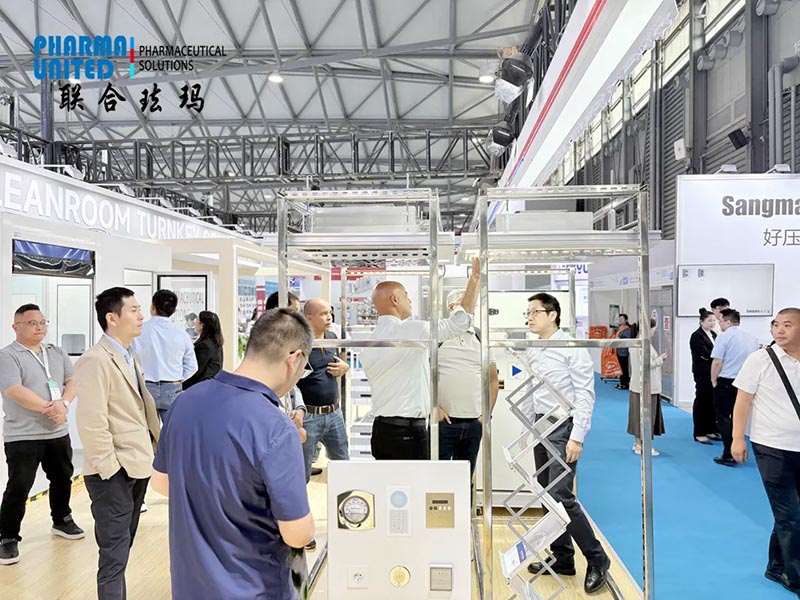

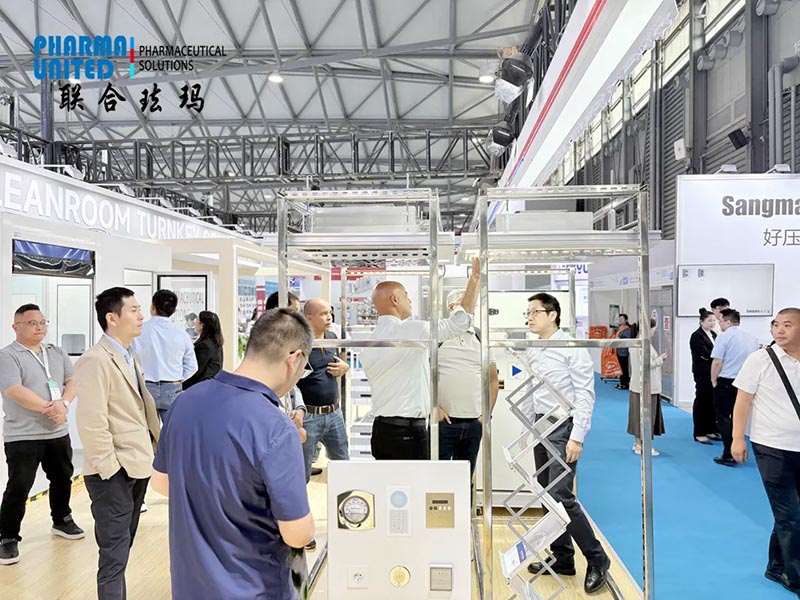

The 23rd edition of CPHI China 2025, a three-day global pharmaceutical ingredients exhibition, recently concluded in Shanghai. Pharma United Co., Ltd. (hereinafter referred to as Pharma United) made a striking appearance with a diversified product lineup including HPL (High-Pressure Laminate) sample rooms, indoor modular models, and metal sample rooms. The showcase vividly demonstrated the company’s deep expertise and cutting-edge innovation in cleanroom partition systems.

The highlight of the booth was undoubtedly Pharma United’s flagship product—the HPL (High-Pressure Laminate) sample room. Its exceptional properties, including resistance to disinfectants, antimicrobial surface, impact and scratch resistance, iodine and chemical resistance, and rust-proof durability, drew a steady stream of visitors. The booth was abuzz with lively discussions and continuous inquiries.

“Unlike metal panels such as sandwich panels, our non-metallic HPL panels are ideally suited for harsh disinfection conditions like hydrogen peroxide (H₂O₂) fumigation and alcohol wiping,” explained a technical expert from Pharma United. “Once scratched, metal panels tend to rust and their coatings can peel off from the damaged area. In contrast, our HPL panels have a higher surface strength. Even if scratched, they do not rust, ensuring long-term durability and consistent quality.”

And the advantages don’t stop there. The technician continued: “Test data shows that Pharma United's HPL panels outperform others in critical metrics like impact resistance, scratch resistance, and wear resistance. Specifically, the impact resistance is more than six times that of sandwich panels or inorganic precoated panels, and scratch and wear resistance are at least twice as high.” This detailed comparison received nods of approval from the attentive audience.

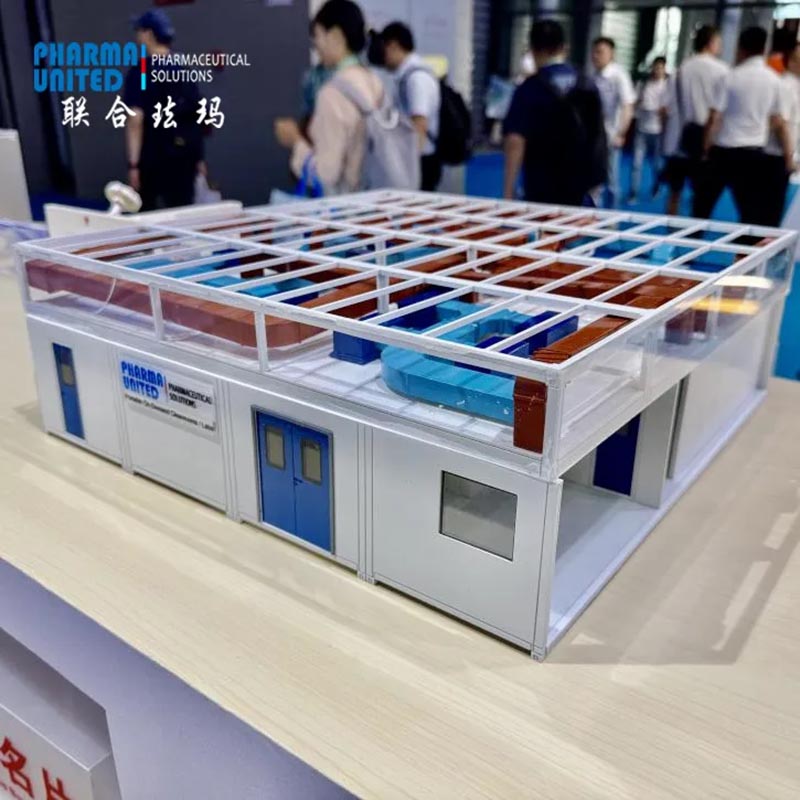

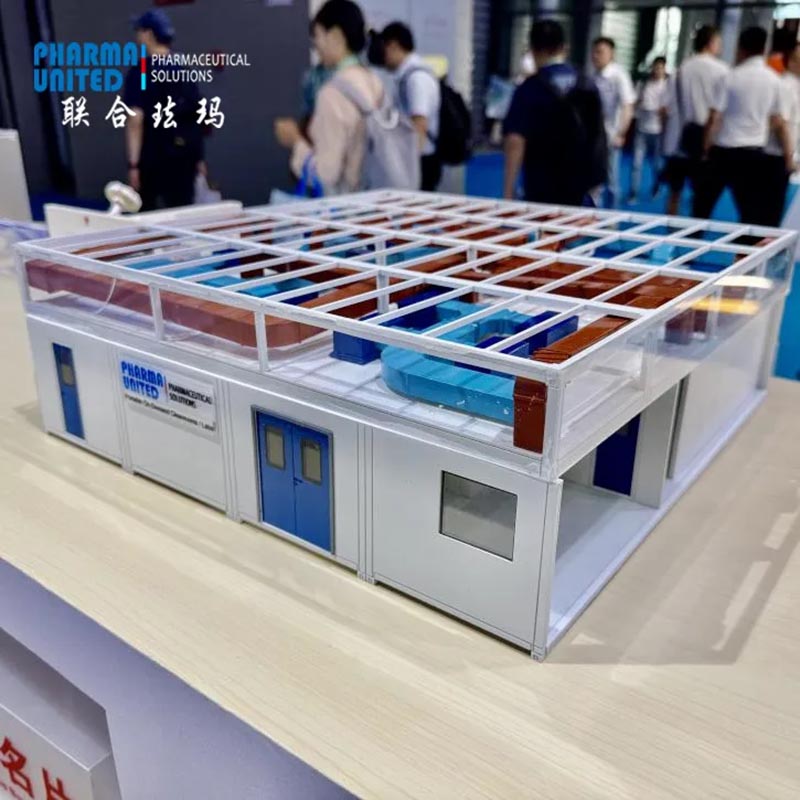

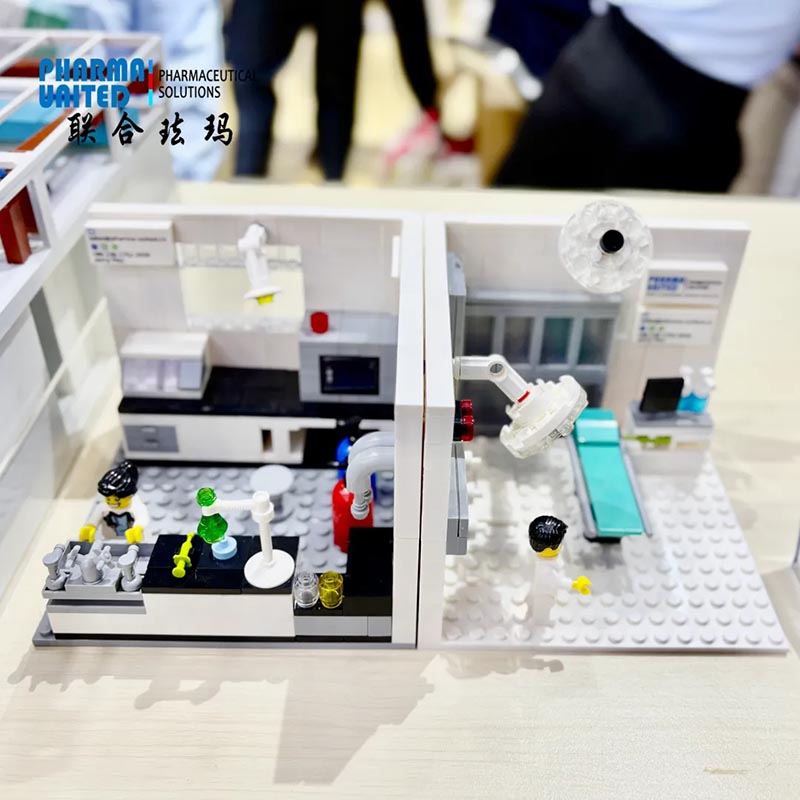

While the HPL sample room demonstrated the static performance of the product, the indoor modular model brought to life Pharma United’s forward-thinking approach to modular construction. The eye-catching scale model at the booth attracted considerable attention. The R&D team adopted an advanced modular design philosophy to break down the traditionally complex cleanroom construction process into manageable units. Key components such as panels, doors, windows, and frames are all precisely prefabricated and pre-adjusted in the factory. Once on-site, only a small number of workers are needed for quick assembly and minor adjustments. This approach can reduce the construction timeline to around 70% of the traditional schedule, significantly saving time and labor costs—making it truly cost-effective. The modular model displayed at the show offered a tangible representation of this efficient construction concept.

Pharma United’s booth remained a hotspot throughout the event. The questions raised by professional visitors were highly focused and technical. One pharmaceutical executive carefully asked about the long-term stability of HPL panels in environments frequently sterilized with high-concentration hydrogen peroxide (VHP). A project manager planning a plant expansion was more intrigued by the modular model, directly inquiring: “You claim a 70% reduction in construction time—how is that guaranteed in real projects? And can the sealing between modules meet the requirements of a Grade C cleanroom?”

Pharma United’s technical team, armed with samples and detailed schematics, responded thoroughly: “Our HPL panels have undergone rigorous testing and have shown stable performance in 3% hydrogen peroxide environments. Their VHP resistance has been fully validated. As for modular construction, the core lies in precision factory prefabrication and standardized interfaces. This ensures airtightness that meets cleanroom standards, and its efficiency has been proven in multiple real-world projects.” Such in-depth professional discussions were ongoing throughout the booth.

According to incomplete on-site statistics, during the three-day exhibition, Pharma United welcomed hundreds of professional visitors, with the number of in-depth business discussions far exceeding expectations. Several companies expressed clear interest in collaboration on the spot, scheduling follow-up factory visits and technical exchanges.

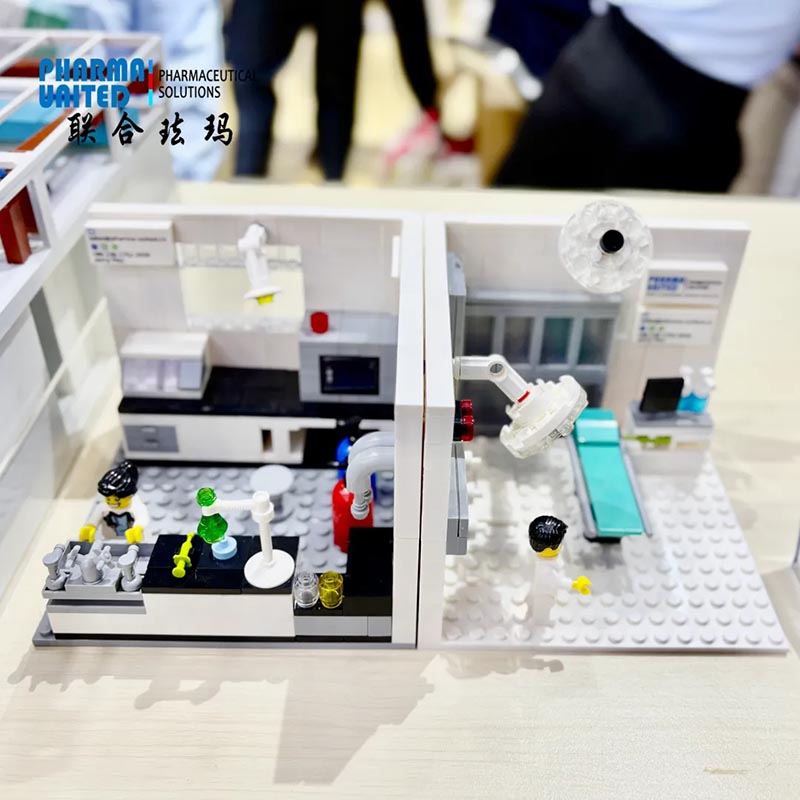

Beyond the technical showcase, Pharma United also created a vibrant VIP lounge. The aroma of freshly brewed coffee filled the air, while the dart game area sparked laughter and cheers. Custom-made name tags and the uniquely creative "laboratory building blocks" giveaways became popular collectibles among new and returning visitors, adding a fun and memorable touch to the exhibition experience.

Pharma United’s brilliant presence at CPHI China 2025 showcased its strong product capabilities and growing global influence. Moving forward, Pharma United will continue to build on the trust and expectations of its clients, driving technological innovation and consistently delivering cutting-edge products aligned with the evolving needs of the pharmaceutical cleanroom industry.